Nindakake tugas kanthi lengkap kanggo nyukupi kabeh kabutuhan para pembeli; entuk kemajuan terus-terusan kanthi ningkatake kemajuan para klien; dadi mitra kerjasama permanen pungkasan para klien lan ngoptimalake kapentingan para pembeli kanggo Pabrik DN25 DN40 DN80 DN100 DN150 DN600 Weld Neck Forging Flens, keuntungan lan kepuasan pelanggan biasane dadi tujuan paling gedhe kita. Elinga hubungi kita. Wenehana kita kesempatan, wenehi kejutan kanggo sampeyan.

Nduweni kewajiban penuh kanggo nyukupi kabeh kabutuhan para pembeli; entuk kemajuan terus-terusan kanthi ningkatake kemajuan para klien; dadi mitra kerja sama permanen pungkasan para klien lan ngoptimalake kapentingan para pembeli kanggoFlensa Pompa Sentrifugal Tempa Cina, Flensa Leher LasKontrol kualitas sing ketat ditindakake ing saben link saka kabeh proses produksi. Kita pancen ngarep-arep bisa netepake kerjasama sing ramah lan saling migunani karo sampeyan. Adhedhasar solusi kualitas dhuwur lan layanan pra-penjualan / sawise-penjualan sing sampurna minangka ide kita, sawetara klien wis kerja sama karo kita luwih saka 5 taun.

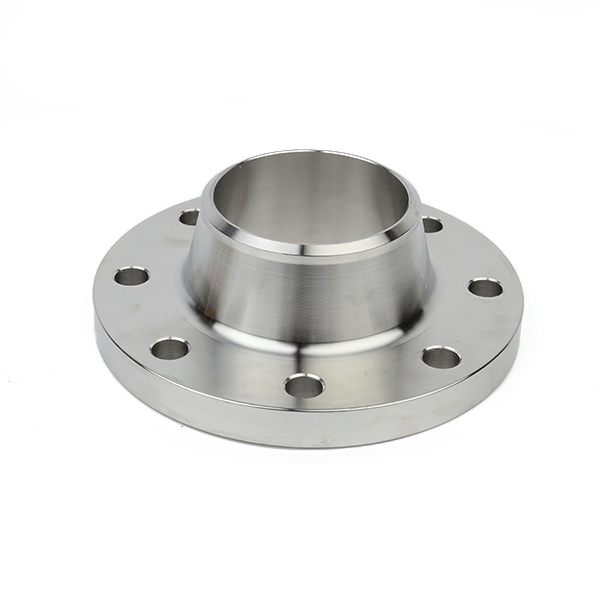

SPESIFIKASI

| Jeneng Produk | Sambungan pangkuan/flensa longgar |

| Ukuran | 1/2"-24" |

| Tekanan | 150#-2500#,PN0.6-PN400,5K-40K |

| Standar | ANSI B16.5, EN1092-1, JIS B2220 etc. |

| Ujung rintisan | MSS SP 43, ASME B16.9 |

| Bahan | Baja tahan karat:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571,1.4541, 254Mo lan liya-liyane. |

| Baja karbon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 lan liya-liyane. | |

| Baja tahan karat dupleks:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 lan liya-liyane. | |

| Pipa baja:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 lan liya-liyane. | |

| Paduan nikel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 lan liya-liyane. | |

| Paduan Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo, lan liya-liyane. | |

| Aplikasi | Industri petrokimia; industri penerbangan lan dirgantara; industri farmasi; knalpot gas; pembangkit listrik; pembangunan kapal; pangolahan banyu, lan liya-liyane. |

| Kauntungan | Stok ready, wektu pangiriman luwih cepet; kasedhiya ing kabeh ukuran, disesuaikan; kualitas dhuwur |

STANDAR DIMENSI

PAMERAN DETAIL PRODUK

1. Rai

Bisa digawe rai munggah (RF), rai lengkap (FF), sendi dering (RTJ), alur, ilat, utawa disesuaikan.

2. Ujung miring miturut ANSI B16.25

3. CNC alus rampung.

Rampungan rai: Rampungan ing rai flens diukur minangka Arithmetical Average Roughness Height (AARH). Rampungan ditemtokake dening standar sing digunakake. Contone, ANSI B16.5 nemtokake rampungan rai ing kisaran 125AARH-500AARH (3.2Ra nganti 12.5Ra). Rampungan liyane kasedhiya miturut panyuwunan, contone 1.6 Ra maks, 1.6/3.2 Ra, 3.2/6.3Ra utawa 6.3/12.5Ra. Kisaran 3.2/6.3Ra paling umum.

TANDA LAN PENGEMASAN

• Saben lapisan nggunakake film plastik kanggo nglindhungi permukaan

• Kanggo kabeh baja tahan karat dikemas nganggo kothak kayu lapis. Kanggo ukuran sing luwih gedhe, flens karbon dikemas nganggo palet kayu lapis. Utawa bisa disesuaikan karo kemasan.

• Tandha pengiriman bisa digawe miturut panyuwunan

• Tandha ing produk bisa diukir utawa dicetak. OEM ditampa.

INSPEKSI

• Tes UT

• Tes PT

• Tes MT

• Tes dimensi

Sadurunge pangiriman, tim QC kita bakal ngatur uji NDT lan inspeksi dimensi. Uga nampa TPI (inspeksi pihak katelu).

PROSES PRODUKSI

| 1. Pilih bahan baku asli | 2. Potong bahan mentah | 3. Pra-pemanasan |

| 4. Tempa | 5. Perawatan panas | 6. Mesin Kasar |

| 7. Pengeboran | 8. Mesin alus | 9. Nandhani |

| 10. Inspeksi | 11. Pengepakan | 12. Pangiriman |

KASUS KERJASAMA

Minangka proyèk ing Turki, flensa digunakaké ing pipa gas alam. Kabèh flensa kuwi wis disetujoni déning TUV.

LEMBAR DATA FLANGE

1. Dimensi lan toleransi flens kudu miturut ASME B16.5.

2. Flensa kudu diprodhuksi kanthi cara ditempa.

3. Bahan kudu miturut standar ASTM A105, ASTM A694 F65 lan ASTM A694 F70.

4. Flensa ASTM A694 F65 lan ASTM A694 F70 kudu didinginkan lan ditemper.

5. Sertifikat uji materi lan laporan perlakuan panas kudu kasedhiya kanggo inspeksi TPI.

6. Flensa WN kudu nganggo ujung miring miturut ASME B16.25.

7. Nilai uji kimia lan mekanik bahan (impak, luluh, tarik, lan liya-liyane) kudu miturut standar sing gegandhengan.

8. Kabeh permukaan kudu diolah nganggo mesin lan divernis nganggo lenga transparan supaya ora karat.

9. Tandha kudu kalebu informasi ing ngisor iki,

• Diameter (kadaluwarsa 6”)

• Kelas tekanan (ex. 150 LB)

• Kelas Bahan (wis lulus ASTM A 105)

• Kekandelan tembok (bisa uga 4,78 mm)

• Ora Ana Panas (kadaluwarsa 138413)

• Standar produksi (ASME B16.5)

10. Bahan kudu bebas saka cacat lan retakan ing permukaan. Perbaikan pengelasan dilarang banget.

11. Kabeh flensa kudu digawe kanthi permukaan sing luwih dhuwur (RF) kanthi permukaan sealing. Permukaan sealing kudu Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) miturut ASME B46.1.

12. Bahan kudu dikemas kanggo nyegah kerusakan ing mesin, lan permukaan sing disegel.

13. Kabeh dimensi kudu ana ing toleransi positif (+). Toleransi minus dilarang banget.

14. Bevelling flens kudu digawe miturut ASME B16.25.

15. Proses manufaktur bakal dipriksa kapan wae dening TPI.

16. TPI bisa njupuk sampel saka bahan apa wae kanggo sampel uji kimia/mekanik.

17. Laporan inspeksi sing mlebu kudu ditliti dening TPI.

| Barang | Ukuran (Inci) | Kelas Tekanan | CS | Bahan | Berat (mm) | Lokasi | Jumlah. |

| SORF | 12 | 150 LB | 20 | A105 | - | Flensa Tangki | 48 |

| SORF | 8 | 150 LB | 20 | A105 | - | Flensa Tangki | 32 |

| SORF | 3 | 150 LB | 20 | A105 | - | Flensa Tangki | 32 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 14 | Flensa Tangki | 2 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 5.54 | Flensa Tangki | 4 |

| SORF | 20 | 150 LB | 20 | A105 | - | Flensa Tangki | 6 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 5.54 | Flensa Tangki | 8 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 14 | Flensa Tangki | 8 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 16 | Flensa Tangki | 8 |

| SORF | 3 | 150 LB | 20 | A105 | - | Flensa Tangki | 24 |

| SORF | 20 | 150 LB | 20 | A105 | - | Flensa Tangki | 6 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 5.54 | Flensa Tangki | 8 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 14 | Flensa Tangki | 16 |

| Barang | Ukuran (Inci) | Kelas Tekanan | CS | Bahan | Berat (mm) | Lokasi | Jumlah. |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flensa, Leher Las | 12 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flensa, Leher Las | 4 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flensa, Leher Las | 4 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flensa, Leher Las | 12 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flensa, Leher Las | 4 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flensa, Leher Las | 10 | 300 LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flensa, Leher Las | 6 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flensa, Leher Las | 4 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flensa, Leher Las | 18 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flensa, Leher Las | 8 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flensa, Leher Las | 8 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Nindakake tugas kanthi lengkap kanggo nyukupi kabeh kabutuhan para pembeli; entuk kemajuan terus-terusan kanthi ningkatake kemajuan para klien; dadi mitra kerjasama permanen pungkasan para klien lan ngoptimalake kapentingan para pembeli kanggo Factory Outlets China Malleable DN25 DN40 DN80 DN100 DN150 DN600 Metal Decorative Pipe Fitting 304 Stainless Steel Weld Neck Forging Centrifugal Pump Flange, Keuntungan lan kepuasan pelanggan biasane dadi tujuan paling gedhe. Elinga hubungi kita. Wenehana kita kesempatan, menehi sampeyan kejutan.

Factory Outlets China Forging Centrifugal Pump Flens, Weld Leher Flens, Kontrol kualitas sing ketat ditindakake ing saben link saka kabeh proses produksi. Kita pancen ngarep-arep bisa netepake kerjasama sing ramah lan saling menguntungkan karo sampeyan. Adhedhasar solusi kualitas dhuwur lan layanan pra-penjualan/purna jual sing sampurna minangka ide kita, sawetara klien wis kerja sama karo kita luwih saka 5 taun.

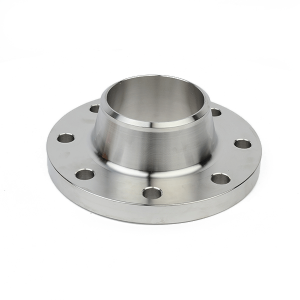

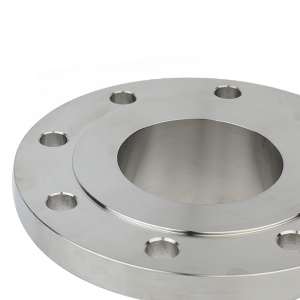

PAMERAN DETAIL PRODUK

1. Rai

Bisa digawe rai munggah (RF), rai lengkap (FF), sendi dering (RTJ), alur, ilat, utawa disesuaikan.

2. Ujung miring miturut ANSI B16.25

3. CNC alus rampung.

Rampungan rai: Rampungan ing rai flens diukur minangka Arithmetical Average Roughness Height (AARH). Rampungan ditemtokake dening standar sing digunakake. Contone, ANSI B16.5 nemtokake rampungan rai ing kisaran 125AARH-500AARH (3.2Ra nganti 12.5Ra). Rampungan liyane kasedhiya miturut panyuwunan, contone 1.6 Ra maks, 1.6/3.2 Ra, 3.2/6.3Ra utawa 6.3/12.5Ra. Kisaran 3.2/6.3Ra paling umum.

TANDA LAN PENGEMASAN

• Saben lapisan nggunakake film plastik kanggo nglindhungi permukaan

• Kanggo kabeh baja tahan karat dikemas nganggo kothak kayu lapis. Kanggo ukuran sing luwih gedhe, flens karbon dikemas nganggo palet kayu lapis. Utawa bisa disesuaikan karo kemasan.

• Tandha pengiriman bisa digawe miturut panyuwunan

• Tandha ing produk bisa diukir utawa dicetak. OEM ditampa.

INSPEKSI

• Tes UT

• Tes PT

• Tes MT

• Tes dimensi

Sadurunge pangiriman, tim QC kita bakal ngatur uji NDT lan inspeksi dimensi. Uga nampa TPI (inspeksi pihak katelu).

PROSES PRODUKSI

| 1. Pilih bahan baku asli | 2. Potong bahan mentah | 3. Pra-pemanasan |

| 4. Tempa | 5. Perawatan panas | 6. Mesin Kasar |

| 7. Pengeboran | 8. Mesin alus | 9. Nandhani |

| 10. Inspeksi | 11. Pengepakan | 12. Pangiriman |

KASUS KERJASAMA

Minangka proyèk ing Turki, flensa digunakaké ing pipa gas alam. Kabèh flensa kuwi wis disetujoni déning TUV.

LEMBAR DATA FLANGE

1. Dimensi lan toleransi flens kudu miturut ASME B16.5.

2. Flensa kudu diprodhuksi kanthi cara ditempa.

3. Bahan kudu miturut standar ASTM A105, ASTM A694 F65 lan ASTM A694 F70.

4. Flensa ASTM A694 F65 lan ASTM A694 F70 kudu didinginkan lan ditemper.

5. Sertifikat uji materi lan laporan perlakuan panas kudu kasedhiya kanggo inspeksi TPI.

6. Flensa WN kudu nganggo ujung miring miturut ASME B16.25.

7. Nilai uji kimia lan mekanik bahan (impak, luluh, tarik, lan liya-liyane) kudu miturut standar sing gegandhengan.

8. Kabeh permukaan kudu diolah nganggo mesin lan divernis nganggo lenga transparan supaya ora karat.

9. Tandha kudu kalebu informasi ing ngisor iki,

• Diameter (kadaluwarsa 6”)

• Kelas tekanan (ex. 150 LB)

• Kelas Bahan (wis lulus ASTM A 105)

• Kekandelan tembok (bisa uga 4,78 mm)

• Ora Ana Panas (kadaluwarsa 138413)

• Standar produksi (ASME B16.5)

10. Bahan kudu bebas saka cacat lan retakan ing permukaan. Perbaikan pengelasan dilarang banget.

11. Kabeh flensa kudu digawe kanthi permukaan sing luwih dhuwur (RF) kanthi permukaan sealing. Permukaan sealing kudu Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) miturut ASME B46.1.

12. Bahan kudu dikemas kanggo nyegah kerusakan ing mesin, lan permukaan sing disegel.

13. Kabeh dimensi kudu ana ing toleransi positif (+). Toleransi minus dilarang banget.

14. Bevelling flens kudu digawe miturut ASME B16.25.

15. Proses manufaktur bakal dipriksa kapan wae dening TPI.

16. TPI bisa njupuk sampel saka bahan apa wae kanggo sampel uji kimia/mekanik.

17. Laporan inspeksi sing mlebu kudu ditliti dening TPI.

| Barang | Ukuran (Inci) | Kelas Tekanan | CS | Bahan | Berat (mm) | Lokasi | Jumlah. |

| SORF | 12 | 150 LB | 20 | A105 | - | Flensa Tangki | 48 |

| SORF | 8 | 150 LB | 20 | A105 | - | Flensa Tangki | 32 |

| SORF | 3 | 150 LB | 20 | A105 | - | Flensa Tangki | 32 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 14 | Flensa Tangki | 2 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 5.54 | Flensa Tangki | 4 |

| SORF | 20 | 150 LB | 20 | A105 | - | Flensa Tangki | 6 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 5.54 | Flensa Tangki | 8 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 14 | Flensa Tangki | 8 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 16 | Flensa Tangki | 8 |

| SORF | 3 | 150 LB | 20 | A105 | - | Flensa Tangki | 24 |

| SORF | 20 | 150 LB | 20 | A105 | - | Flensa Tangki | 6 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 5.54 | Flensa Tangki | 8 |

| Flensa, Leher Las | 24 | 150 LB | 20 | A105 | 14 | Flensa Tangki | 16 |

| Barang | Ukuran (Inci) | Kelas Tekanan | CS | Bahan | Berat (mm) | Lokasi | Jumlah. |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flensa, Leher Las | 12 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flensa, Leher Las | 4 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flensa, Leher Las | 4 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flensa, Leher Las | 20 | 400 LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flensa, Leher Las | 12 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flensa, Leher Las | 24 | 400 LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flensa, Leher Las | 4 | 400 LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flensa, Leher Las | 10 | 300 LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flensa, Leher Las | 6 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flensa, Leher Las | 4 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flensa, Leher Las | 18 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flensa, Leher Las | 8 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flensa, Leher Las | 8 | 300 LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Piranti sambungan pipa minangka komponen penting ing sistem perpipaan, digunakake kanggo sambungan, pangalihan, pengalihan, pangowahan ukuran, penyegelan utawa ngontrol aliran cairan. Piranti iki digunakake sacara wiyar ing bidang-bidang kayata konstruksi, industri, energi lan layanan kotamadya.

Fungsi Utama:Bisa nindakake fungsi kaya nyambungake pipa, ngganti arah aliran, mbagi lan nggabungake aliran, nyetel diameter pipa, nyegel pipa, ngontrol lan ngatur.

Cakupan Aplikasi:

- Pasokan banyu lan drainase bangunan:Siku PVC lan tris PPR digunakake kanggo jaringan pipa banyu.

- Pipa industri:Flensa baja tahan karat lan siku baja paduan digunakake kanggo ngangkut media kimia.

- Transportasi energi:Pipa baja tekanan tinggi digunakake ing pipa lenga lan gas.

- HVAC (Pemanas, Ventilasi, lan AC):Sambungan pipa tembaga digunakake kanggo nyambungake pipa refrigeran, lan sambungan fleksibel digunakake kanggo ngurangi getaran.

- Irigasi pertanian:Konektor cepet nggampangake perakitan lan pembongkaran sistem irigasi sprinkler.