SPESIFIKASI

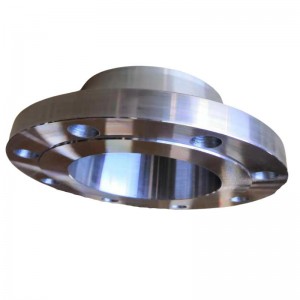

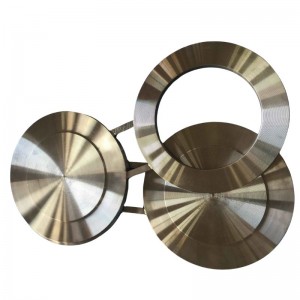

| Jeneng produk | weld neck flange |

| Ukuran | 1/2"-24" |

| Tekanan | 150#-2500#,PN0.6-PN400,5K-40K |

| Standar | ANSI B16.5, EN1092-1, JIS B2220 etc. |

| Stub mburi | MSS SP 43, ASME B16.9 |

| Bahan | Baja tahan karat:A182F304 / 304L, A182 F316 / 316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317 / 317L, 904L, 1.4301, 1.4301, 1.4301, 1.4301, 1.4104 54Mo lan liya-liyane. |

| Baja karbon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 lsp. | |

| Duplex stainless steel:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462,1.4410,1.4501 lan liya-liyane. | |

| Pipa baja:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 etc. | |

| Paduan nikel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 etc. | |

| Paduan Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3,15Crmo, lsp. | |

| Aplikasi | Industri petrokimia; industri penerbangan lan aeroangkasa; industri farmasi; knalpot gas; pembangkit listrik; bangunan kapal; perawatan banyu, lsp. |

| Kaluwihan | stok siap, wektu pangiriman luwih cepet; kasedhiya ing kabeh ukuran, disesuaikan; kualitas dhuwur |

STANDAR DIMENSI

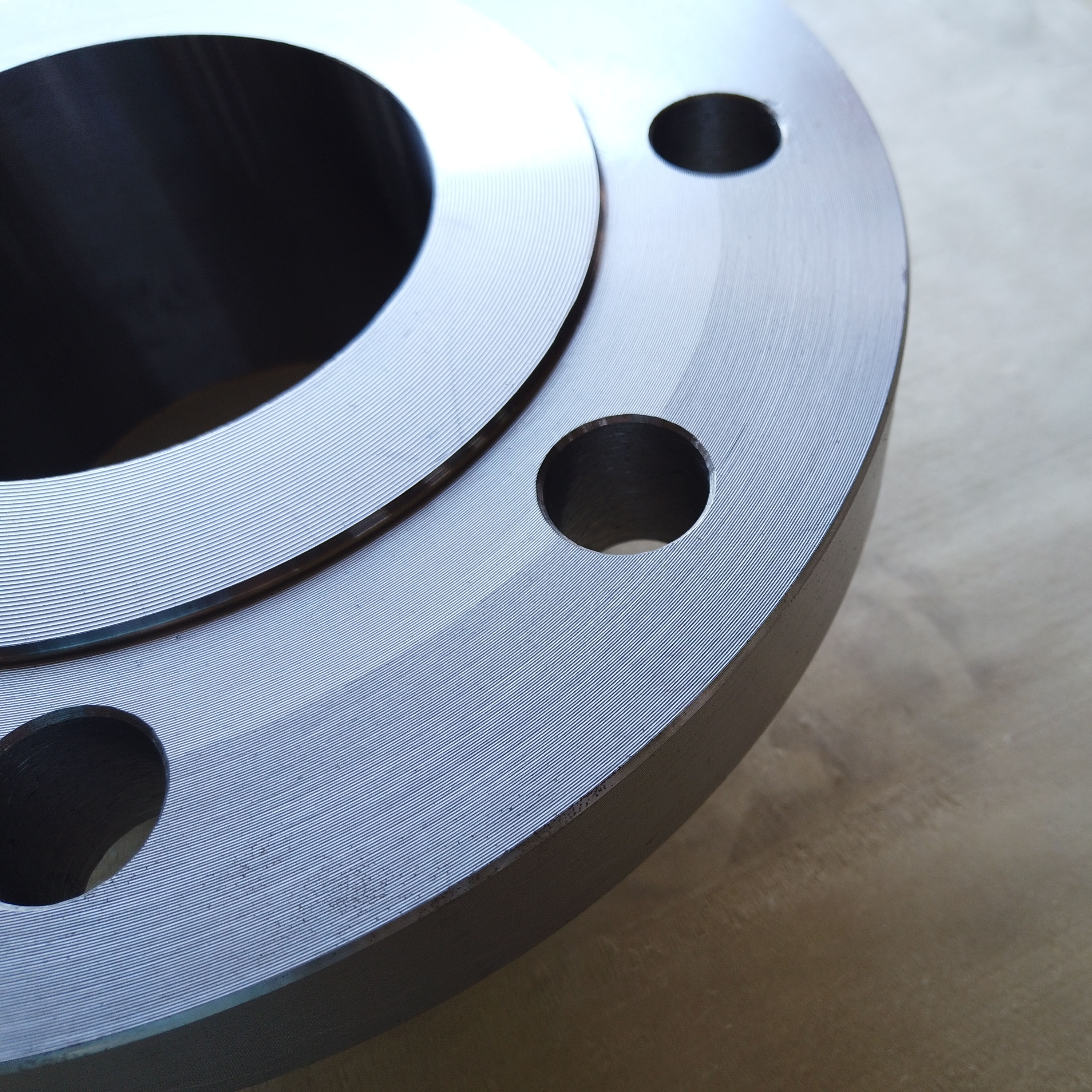

PRODUK DETAIL SHOW

1. Pasuryan

Bisa diangkat pasuryan (RF), pasuryan lengkap (FF), Ring joint (RTJ), Alur, Ilat, utawa selaras.

2. Bevel pungkasan minangka saben ANSI B16.25

3.CNC nggoleki rampung.

Rampung rai: Rampung ing pasuryan flange diukur minangka Dhuwur Kekasaran Rata-rata Aritmetika (AARH).Rampung ditemtokake dening standar sing digunakake.Contone, ANSI B16.5 nemtokake rai rampung ing sawetara 125AARH-500AARH(3.2Ra kanggo 12.5Ra).Rampung liyane kasedhiya ing requst, contone 1,6 Ra max, 1,6 / 3,2 Ra, 3,2 / 6,3Ra utawa 6,3 / 12,5Ra.Kisaran 3.2/6.3Ra paling umum.

MARKING lan PACKING

• Saben lapisan nggunakake film plastik kanggo nglindhungi lumahing

• Kanggo kabeh stainless steel dikempalken dening cilik plywood.Kanggo flange karbon ukuran luwih gedhe dikempalken dening pallet plywood.Utawa bisa selaras packing.

• tandha Shipping bisa nggawe ing request

• Tandha ing produk bisa diukir utawa dicithak.OEM ditampa.

PEMERIKSAAN

• tes UT

• Tes PT

• test MT

• Tes ukuran

Sadurunge pangiriman, tim QC kita bakal ngatur test NDT lan ukuran inspection.Also nampa TPI (pengawasan pihak katelu).

PROSES PRODUKSI

| 1. Pilih bahan baku Asli | 2. Cut bahan mentahan | 3. Pre-heating |

| 4. Tempa | 5. perawatan panas | 6. Mesin Kasar |

| 7. Pengeboran | 8. Fine maching | 9. Tandha |

| 10. Pamriksan | 11. Pengemasan | 12. Pangiriman |

KASUS KOPERASI

A project ing Turki, flanges digunakake ing pipelines gas alam.Kabeh flange kasebut disetujoni dening TUV.

LEMBAR DATA FLANGE

1.Ukuran lan toleransi flange kudu miturut ASME B16.5.

2. Flanges bakal diprodhuksi dening forging.

3. Bahan kudu miturut standar ASTM A105, ASTM A694 F65 lan ASTM A694 F70.

4. ASTM A694 F65 lan ASTM A694 F70 flanges bakal quenched lan tempered.

5. Sertifikat tes material lan laporan perawatan panas kudu kasedhiya kanggo pemeriksaan TPI.

6. WN flanges kudu karo bevel ends acc.kanggo ASME B16.25.

7. Nilai tes kimia lan mekanik bahan (impact, yield, tensile etc.) kudu miturut standar sing gegandhengan.

8. Kabeh lumahing bakal machined lan varnished karo lenga transparent kanggo nyegah rusting.

9. Tandha kudu kalebu informasi ing ngisor iki,

• Dhiameter (exp. 6")

• Kelas tekanan (exp. 150 LB)

• Kelas Material (exp. ASTM A 105)

• Ketebalan tembok (exp. 4,78 mm)

• Nomer Panas (exp. 138413)

• Standar Produksi (ASME B16.5)

10. Bahan kudu bebas saka cacat permukaan lan retak.Diposaken welding sing strictly dilarang.

11. Kabeh flanges kudu wungu pasuryan (RF) karo lumahing sealing.Lumahing sealing kudu Ra 3,2 – 6,3 µm (125 – 250 mic. Inc.) acc.kanggo ASME B46.1.

12. Bahan bakal dikempalken kanggo nyegah karusakan kanggo mesin, lan lumahing sealing.

13. Kabeh dimensi kudu positif (+) toleransi.Toleransi minus dilarang banget.

14. Flange bevellings kudu digawe acc.kanggo ASME B16.25.

15. Proses manufaktur bakal dipriksa sawayah-wayah dening TPI.

16. TPI bisa njupuk conto saka materi apa wae kanggo sampel uji kimia/mekanik.

17. Laporan inspeksi sing mlebu kudu ditinjau dening TPI.

| Item | Ukuran (Inci) | Kelas Tekanan | CS | Bahan | WT (mm) | Panggonan | Qty. |

| SORF | 12 | 150LB | 20 | A105 | - | TANGKI FLANGES | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | TANGKI FLANGES | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | TANGKI FLANGES | 32 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANGKI FLANGES | 2 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANGKI FLANGES | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | TANGKI FLANGES | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANGKI FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANGKI FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 16 | TANGKI FLANGES | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | TANGKI FLANGES | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | TANGKI FLANGES | 6 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 5.54 | TANGKI FLANGES | 8 |

| Flange, Weld Neck | 24 | 150LB | 20 | A105 | 14 | TANGKI FLANGES | 16 |

| Item | Ukuran (Inci) | Kelas Tekanan | CS | Bahan | WT (mm) | Panggonan | Qty. |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Weld Neck | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Weld Neck | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Weld Neck | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Weld Neck | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Weld Neck | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Weld Neck | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Weld Neck | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Weld Neck | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

FAQ

1. Apa AMSE B16.5 A105 palsu baja karbon butt welding flange?

AMSE B16.5 A105 Forged Carbon Steel Butt Weld Flange nuduhake jinis flange tartamtu sing digunakake ing sistem pipa.Iki digawe saka baja karbon A105 lan nduweni desain gulu sing dilas kanggo nyedhiyakake sambungan sing aman lan anti bocor.

2. Apa fitur utama AMSE B16.5 A105 baja karbon palsu welding flange?

Fitur utama AMSE B16.5 A105 flanges butt weld baja karbon palsu kalebu kekuatan dhuwur, daya tahan lan tahan karat.Iki dirancang kanggo tahan tekanan dhuwur lan aplikasi suhu dhuwur ing lingkungan industri.

3. Where AMSE B16.5 A105 baja karbon palsu welding flange bisa digunakake?

AMSE B16.5 A105 flange las butt baja karbon palsu digunakake ing macem-macem industri, kalebu lenga lan gas, petrokimia, pembangkit listrik lan perawatan banyu.Asring digunakake ing sistem pipa kanggo nyambungake pipa utawa katup kanthi aman.

4. Carane nginstal AMSE B16.5 A105 palsu baja karbon butt welding flange?

Kanggo nginstal AMSE B16.5 A105 baja karbon palsu las las flange, pisanan las flange menyang pipa utawa mburi tutup.Gulu las banjur disambungake menyang flange sing cocog ing pipa utawa piranti liyane nggunakake bolts lan washers kanggo nggawe sambungan sing nyenyet lan bocor.

5. Apa sing kaluwihan saka nggunakake AMSE B16.5 A105 palsu karbon baja butt welding flanges?

Sawetara kaluwihan nggunakake AMSE B16.5 A105 palsu baja karbon bokong las flanges kalebu construction kekuatan dhuwur, kang njamin sambungan dipercaya lan long-tahan.Dheweke uga nyedhiyakake aliran cairan lan gas sing lancar, nyuda turbulensi, lan nyuda erosi utawa karat.

6. Apa ukuran lan meksa HFS opsi kasedhiya kanggo AMSE B16.5 A105 palsu baja karbon butt weld flanges?

AMSE B16.5 A105 Forged Carbon Steel Butt Weld Flanges kasedhiya ing macem-macem ukuran, kiro-kiro saka 1/2 "nganti 36" ing diameteripun.Padha uga teka ing macem-macem tingkat tekanan kayata 150, 300, 600, 900, 1500 lan 2500.

7. Carane kanggo mesthekake sambungan bocor-free karo AMSE B16.5 A105 palsu baja karbon bokong las flanges?

Kanggo mesthekake sambungan bebas bocor karo AMSE B16.5 A105 baja karbon palsu las flensa butt, flanges kudu didadekake siji kanthi bener sadurunge tightening bolts.Torsi bolt sing cukup kudu ditrapake miturut spesifikasi sing disaranake kanggo entuk sambungan sing aman lan aman.

8. Bisa AMSE B16.5 A105 palsu baja karbon bokong las flanges digunakake ing meksa dhuwur lan aplikasi suhu dhuwur?

Ya, AMSE B16.5 A105 palsu baja karbon bokong las flanges dirancang kanggo tahan tekanan dhuwur lan kahanan suhu dhuwur.Nanging, penting kanggo mesthekake yen flange lan komponen sing gegandhengan kompatibel karo kondisi operasi tartamtu kanggo njaga integritas sambungan kasebut.

9. Apa AMSE B16.5 A105 palsu baja karbon butt weld flanges mbutuhake bahan sealing tambahan?

Ya, AMSE B16.5 A105 palsu baja karbon bokong las flanges mbutuhake nggunakake gaskets kanggo nyedhiyani segel antarane flange pasuryan.Bahan gasket gumantung saka jinis cairan utawa gas sing dikirim lan kahanan operasi.Milih bahan gasket sing tepat penting kanggo nyegah bocor.

10. Apa AMSE B16.5 A105 palsu baja karbon bokong welding flanges gampang kasedhiya ing pasar?

Ya, AMSE B16.5 A105 Forged Carbon Steel Butt Weld Flange kasedhiya ing pasar.Iki minangka jinis flange sing umum digunakake sing bisa dituku saka macem-macem dealer resmi lan pabrikan sing duwe spesialisasi ing rakitan pipa.

-

Soket las flange A105 baja karbon SW RTJ 3/4...

-

Ansi B16.5 A105 Black Carbon Steel Slip ing Flange

-

ASME b16.48 Penjualan Pabrik baja karbon angka 8 ...

-

orifice flange WN 4″ 900# RF A105 dual gr...

-

ASTM A182 F51 F53 BL ANSI B16.5 Baja tahan karat...

-

ASME B16.5 BL RF ASTM A182 F316L Baja tahan karat...